Introduction

Fan motors are the unsung heroes of HVAC (Heating, Ventilation, and Air Conditioning) systems. They drive the air movement that makes heating and cooling possible, ensuring comfortable temperatures and proper air circulation in residential, commercial, and industrial buildings. Despite their critical role, fan motors often go unnoticed until a problem arises.

In this guide, we’ll dive into the different types of fan motors, their functions within HVAC systems, the key technical specifications to consider, common issues, and tips for maximizing their efficiency and lifespan.

1. The Role of Fan Motors in HVAC Systems

Fan motors are responsible for circulating air through the ducts, coils, and vents of HVAC systems. They come in various types, each designed for specific applications and efficiency levels. The main roles of fan motors include:

- Air Circulation: Moving conditioned air throughout the building to maintain consistent temperatures.

- Heat Exchange Support: Ensuring that heat exchangers and evaporator coils receive the necessary airflow for efficient heat transfer.

- Pressure Management: Balancing air pressure within the duct system to prevent issues like air leaks and uneven cooling.

- Humidity Control: Supporting dehumidification by maintaining proper airflow over cooling coils.

“Without a properly functioning fan motor, even the most efficient HVAC system will fail to deliver consistent comfort.” — HVAC Performance Standards Manual

2. Types of Fan Motors Used in HVAC Systems

There are several types of fan motors used in HVAC systems, each with its own advantages and ideal applications:

- PSC (Permanent Split Capacitor) Motors: Common in older units, reliable but less efficient. Known for simple design and moderate cost.

- ECM (Electronically Commutated Motors): Highly efficient, variable-speed motors found in modern high-efficiency systems. Offer precise airflow control and lower operating costs.

- Shaded Pole Motors: Low efficiency, primarily used in small fans and less demanding applications.

- BLDC (Brushless DC) Motors: Extremely efficient, found in premium HVAC systems and mini-splits. Offer precise control and longer lifespan.

- Split-Phase Motors: Economical, but lower starting torque. Often used in small exhaust fans.

3. Key Technical Specifications of Fan Motors

Understanding the technical specifications of fan motors is crucial for selecting the right unit and ensuring optimal performance:

- Horsepower (HP): Determines the power output of the motor. Typical residential HVAC systems use 1/4 to 1 HP motors.

- RPM (Revolutions Per Minute): Affects the airflow rate and noise level. High-speed motors move more air but may be louder.

- Voltage and Amperage: Must match the electrical specifications of the HVAC system to avoid overheating and electrical damage.

- Efficiency Rating: ECM and BLDC motors are typically 30-60% more efficient than PSC motors, reducing operating costs.

- Airflow (CFM): The amount of air the motor can move, usually measured in cubic feet per minute.

4. Common Fan Motor Problems and Troubleshooting

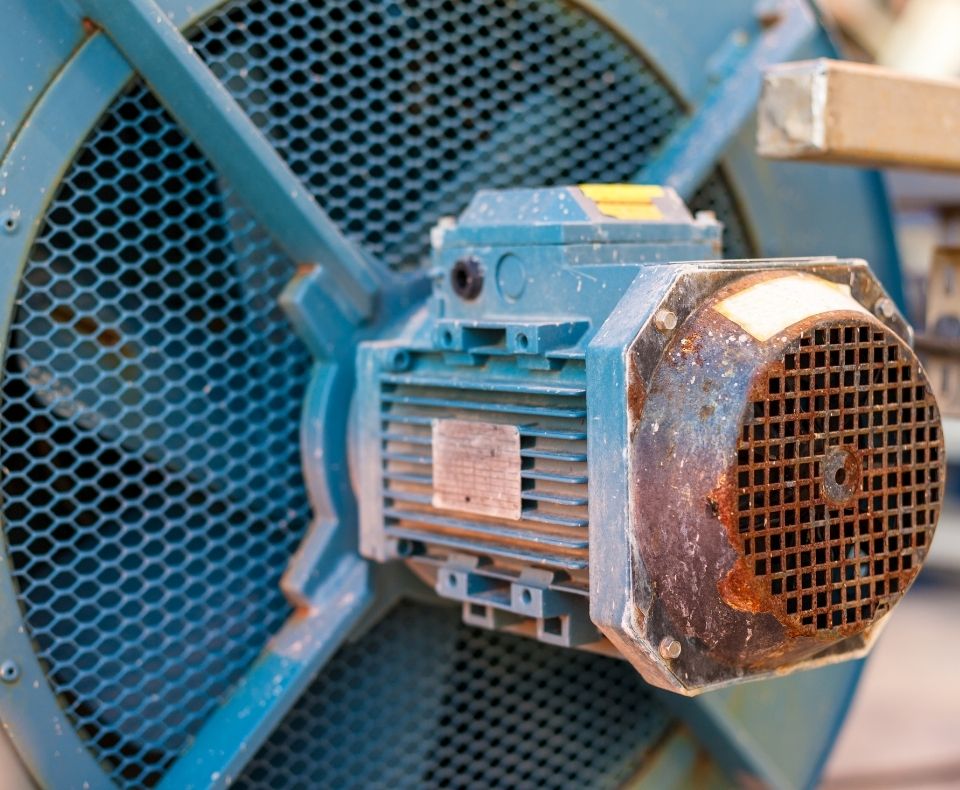

Fan motors are critical components, but they can fail if not properly maintained. Common issues include:

- Overheating: Often caused by dirty coils, clogged filters, or incorrect voltage.

- Bearing Failure: Due to lack of lubrication or excessive load.

- Electrical Issues: Worn-out windings, capacitor failure, or loose connections can cause electrical shorts.

- Noisy Operation: Usually a sign of misalignment, loose mounting, or debris in the housing.

- Reduced Airflow: Could be due to a failing capacitor, dirty blower wheel, or motor winding damage.

“Routine maintenance is critical for extending the life of fan motors and preventing costly breakdowns.” — HVAC Maintenance Best Practices Guide

5. Maintaining and Extending the Life of Fan Motors

To ensure your fan motor runs efficiently and lasts as long as possible, consider these maintenance tips:

- Regular Cleaning: Dust and debris can clog motor vents and reduce cooling efficiency.

- Lubrication: Some motors require periodic oiling to reduce friction and prevent bearing failure.

- Inspect Capacitors: Weak or failing capacitors can reduce starting torque and overall motor efficiency.

- Check Electrical Connections: Loose or corroded terminals can lead to electrical shorts.

- Balance the Load: Ensure ductwork is clean and free of obstructions to reduce motor strain.

6. Upgrading to High-Efficiency Fan Motors

If you’re considering an HVAC system upgrade, investing in a high-efficiency fan motor can significantly reduce operating costs and improve comfort:

- ECM Motors: Offer variable speed control, reducing energy consumption and providing precise temperature control.

- BLDC Motors: Provide the highest efficiency, ideal for homes aiming to reduce carbon footprint.

- Smart Motors: Some newer models integrate with smart thermostats for optimized performance.

Final Thoughts

Fan motors are the beating heart of any HVAC system, playing a critical role in maintaining comfort and efficiency. By understanding the different types of motors, their technical specifications, and proper maintenance, you can extend their lifespan and improve the overall performance of your heating and cooling system.